Automatic lathe and slitting lathe, although both are important types of CNC machine tools, there are significant differences in many aspects. Let me break it down for you:

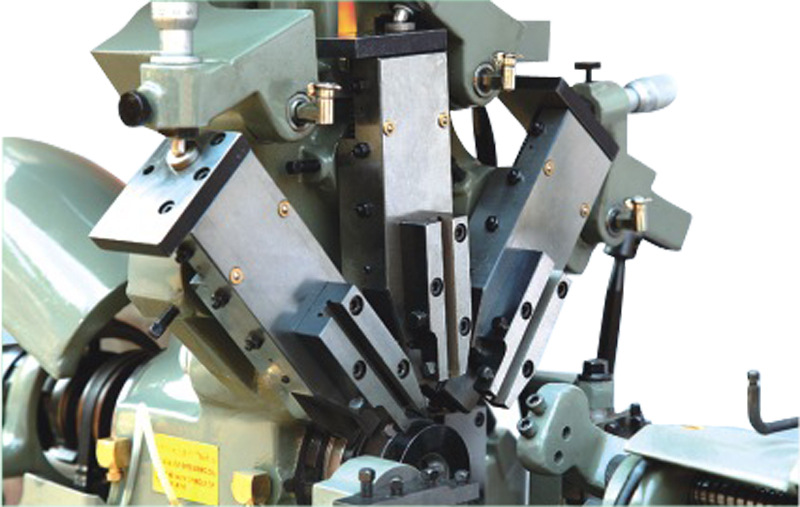

Automatic cutting lathe is shown as follows 1 Longitudinal cutting lathe is shown as follows 2

How it works

Automatic lathe : The main shaft through the rotation of the CAM to complete the cutting work. In the process of machining, the relative movement between the tool and the workpiece is used to cut the workpiece in the form of arc, straight line and diagonal line.

Slinting lathe : The tool is always in a fixed position, and the product is processed by the forward and backward movement of the main shaft Z axis and the rotation of the C axis. This machining method allows the workpiece to be fixed during the machining process and the tool to rotate, thus achieving high-speed and efficient machining.

two, processing methods

cutting automatic lathe : because of the relative movement between the tool and the workpiece, it is excellent in the processing of various shapes of complex parts, such as box, aluminum alloy parts and so on.

Slitter lathe : mainly used for mass processing of precision hardware and non-standard shaft parts, such as wheel hub, bearing sleeve, etc. Because the workpiece is fixed and the tool is rotated, the centring lathe has a significant advantage in machining high-precision, slender shaft parts.

. Scope of application

Automatic lathe : The scope of application is more extensive, can process various shapes of parts, to meet diversified processing needs.

Slitting lathe : more suitable for machining round parts, especially small diameter parts. At the same time, because the machine lathe has a greater advantage in processing accuracy, it is suitable for some occasions with high precision requirements.

four, processing accuracy

Automatic lathe : although it can also achieve the processing accuracy, but compared with the machine lathe, its processing accuracy may be slightly inferior.

Slitter lathe : can achieve very high machining accuracy, dimensional accuracy can reach micron, very suitable for some precision parts processing requirements.

Cost and efficiency

Cutting automatic lathe : With its high flexibility and relatively low cost, it can meet the diversified processing needs and maintain a low production cost.

Slitting lathe : although the price is relatively high, but in the processing of large quantities of products, due to its high-speed and efficient processing characteristics, can significantly improve production efficiency and reduce production costs.

To sum up, there are significant differences between automatic lathe and machine lathe in working principle, processing mode, application scope, processing accuracy and cost efficiency. When selecting processing equipment, it should be comprehensively considered according to the specific processing needs to achieve the processing effect and work efficiency.