Dual spindle CNC lathes and dual spindle Swiss slitting lathes are similar in some respects, but there are also significant differences. Here are the main differences:

Structure and working principle:

Dual-spindle CNC lathe: Usually refers to a CNC machine tool equipped with two spindles that can be processed simultaneously or independently. This machine is suitable for parts processing where high precision and high efficiency are required, especially in cases where multiple clamping or complex processes are required.

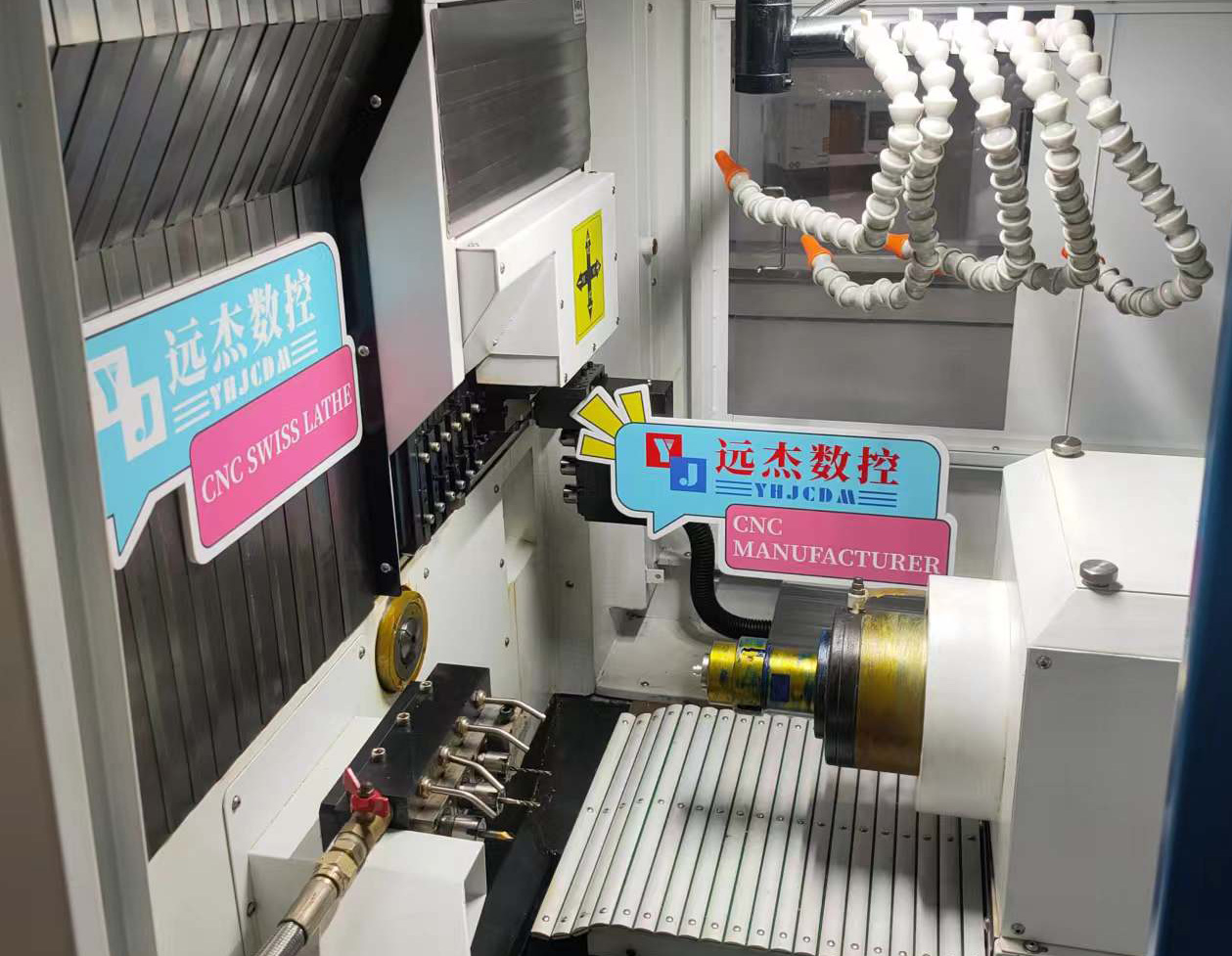

Twin-spindle Swiss slinting lathe: The central machine (also known as the Swiss type automatic lathe) is a special type of CNC machine tool, which is characterized by the continuous advance of the material during the machining process, similar to the process of "moving the center". Dual spindle walking machine is equipped with two spindles, which can complete multiple processes on a single machine tool, further improving production efficiency.

Application field:

Double spindle CNC lathe: widely used in various manufacturing industries, especially parts processing requiring high precision and high efficiency, such as aerospace, automobile manufacturing, yi medical equipment and other fields.

Twin-spindle Swiss slitting lathe: Usually used for machining small, complex parts, such as watches, bicycle parts, precision instruments, etc. Due to its unique core processing method, it is especially suitable for the processing of parts requiring high precision and complex shapes.

Machining efficiency and accuracy: Dual spindle CNC lathes: Because they can be processed simultaneously or independently, production efficiency and machining accuracy can be significantly improved.

Dual spindle Swiss slinting lathe: Because the material is constantly advancing in the processing process, multiple processing steps can be completed in a single process, further improving production efficiency and processing accuracy.

Operation and maintenance:

Dual spindle CNC lathes: More experience in operation and maintenance is usually required to ensure the normal operation and high efficiency of the machine tool.

Twin-spindle Swiss slinting lathes: Due to their unique construction and working principle, specific operating and maintenance skills may be required.

To sum up, although dual-spindle CNC lathes and dual-spindle walking machines are similar in some respects, they have significant differences in structure, application fields, processing efficiency and operation and maintenance. The choice of machine depends on the specific processing needs and application scenarios